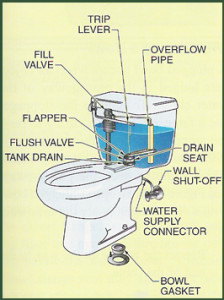

WATER CLOSET TANKS

If water continues to run into the closet bowl after the toilet is flushed it, is obvious that some part of the mechanism is out of order.

When the tank has refilled, if water continues to seep into the bowl or if there is a low humming noise, this indicates leakage from the tank. This leakage can occur from either the supply valve or the improper seating of the rubber tank bailor (flapper) on the discharge opening

A small amount of food coloring added to the tank water will help you determine whether the tank ball in the bottom of the tank is leaking. Add it to the water after the tank is filled. Watch for the coloring to seep into the toilet bowl, and if it does, the bailor flapper over the discharge opening is not water tight If the rubber tank ball does not fit tightly over the discharge opening, a defective ball, irregular seat or bent lift wires may be responsible. If the ball is worn out, misshapen or has lost its elasticity and fails to drop tightly into the hollowed seat, it should be replaced with a new one. Sometimes the ball is covered with a slimy coating which can easily be wiped off. To replace the ball, shut off the water supply (a stop is installed underneath the tank where the water may be conveniently shut off at this point) and empty the tank or place a stick under the ball float lever-arm to hold it up, thereby shutting off the intake cock and preventing the tank from refilling. Then unscrew the ball from the lower lift wire and attach a new ball of the same diameter as the old one. (Note: some old tank balls swell from age and absorption of water.)

If the collar or seat of the discharge opening is corroded or grit-covered, it should be scraped and sand-papered until it is smooth and forms a uniform bearing for the stopper.

Straighten or replace bent lift wires so that the ball drops squarely into the hollowed seat.

A leaky, waterlogged float ball holds the supply valve open and does not completely shut off the water. If the rod which connects the tank float to the supply valve has become bent, it may prevent the float from reaching its full height, thus leaving the valve open and allowing leakage. This rod should be straightened and a little oil applied to the lever joints to insure smooth action.

Sometimes the tank will not fill sufficiently or will fill to overflowing. These difficulties may be corrected without disturbing the supply valve by bending the rod attached to the tank float upward or downward. If the rod is bent upward, the water will rise higher in the tank, and if downward, the water level will be lowered.

An overflow tube or pipe is provided in the closet tank to take care of the water in case it should rise above its accustomed level which should be at least 3/4 of an inch below the top of the overflow. While there is not much danger of its becoming stopped up, it might be well to examine it occasionally to see that it is in working order.